Black zinc electroplating provides automotive parts with consistent deep finishes with a high degree of corrosion protection at a lower cost than zinc-nickel plating. The black trivalent zinc passivate is the topcoat applied after the zinc electroplating process is completed. The topcoat provides added corrosion resistance, excellent heat resistance, and color. Black trivalent zinc passivate finishes are used in a variety of industries including the automotive industry. Great Lakes Metal Finishing provides high tolerance blemish-free black trivalent zinc passivate electroplating for applications like:

- Cosmetic surfaces

- Rugged Automotive Parts

- Interior & Exterior Decorative Parts for Automobile

Black Trivalent Zinc Passivate Plating for Interior/Exterior Automotive Parts

Manufacturers in the automotive industry demand the highest levels of protection from the forces of corrosion. Without plating, rust can spread quickly, causing cosmetic and functional damage. Plating with zinc, such as black trivalent passivate, provides a significant increase in part lifespan. Black zinc can also improve the appearance of an automotive part, adding a shiny characteristic. You can find this cosmetic finish on many types of car and motorcycle parts including under-the-hood components, power steering systems, brake systems, and many decorative automotive parts.

Automotive manufacturers like Nissan and Honda have a list of specifications that fall under different plating processes, such as zinc plating, zinc-nickel plating, stainless steel passivation, and others. In the automotive industry, black trivalent zinc passivate is widely used for part protection and finish. Some of the specs that are associated with this finish are as follows:

Nissan’s NES M 0301-2005-1 Requires MFZN 2TK, 5TK, 8TK & 13TK Specification for Automotive Parts

Nissan Engineering Standard (NES) describes electroplated coatings of black trivalent passivate as platings that are applied to iron and steel for corrosion protection and appearance. Nissan utilizes black trivalent passivate plating(TK) because it uses a black passivate that is free of hexavalent chromium. Great Lakes Metal finishing commonly plates the significant surface according to NES specs, and can provide different levels of protection as required for secondary surfaces. Other standards that fall under NES 0301 include:

- NES M 0140-2001 Methods of Salt Spray Testing

- NES M 2023-2003 Double Wall Welded Steel Tubes

- NES M 0301-2005-1 Substance Use Restrictions

- JIS D 0201-1995 General rules of electroplating for automobile parts

- JIS H 8610-1999 Electroplated coatings of zinc on iron and steel

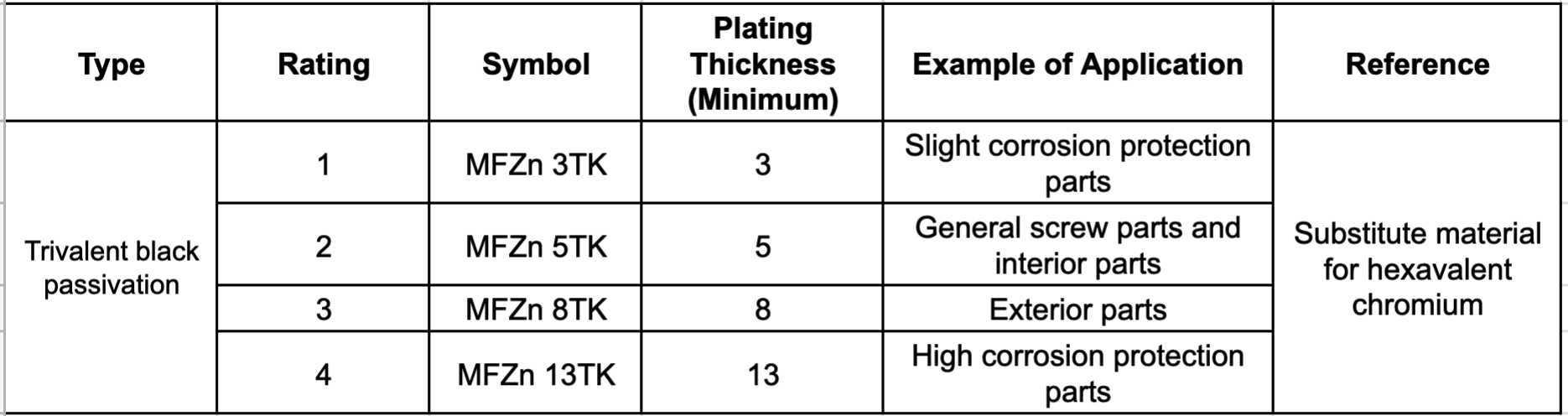

There are a wide variety of plating thicknesses that can be chosen for trivalent black electroplating based on the level of protection required for a given part. Below is a chart differentiating protection levels of trivalent black electroplating for Nissan:

In accordance with NES standards, each part is finished smooth and free from burn deposits, blisters, or exposure of substrate defects. Some substrates that have defects may appear after the process, commonly known as “plating defects” which are not acceptable. However, slight interference fringes or color irregularities, as a result of the treatment, are acceptable.

Honda’s HES D 2003 – 05 Requires MFZn2-K Specification for Black Trivalent Automotive Parts

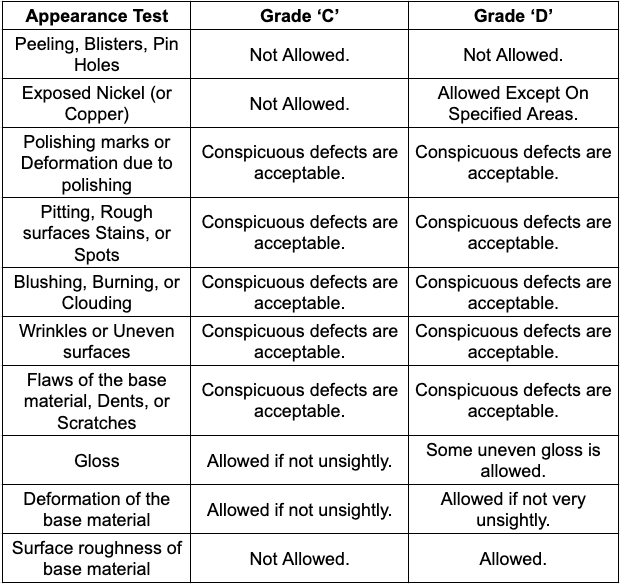

Honda’s HES D 2003-05 standard specifies the black trivalent passivate electroplated coating to be performed for purposes of corrosion prevention, rust prevention, and decoration. Since December 2005, the inclusion of hexavalent chromium in the coating has been made prohibited by Honda. Great Lakes Metal Finishing offers the specific black trivalent passivate electroplating, MFZn2-K. All platings are categorized by appearance, corrosion resistance, plating thickness, adhesions, and more. Each of these characteristics requires a series of tests. These tests include:

- Appearance Test in HES D 6001

- Thickness Test in HES D 6001

- Corrosion Resistance Test in HES D 6001

- Adhesion Test in HES D 6001

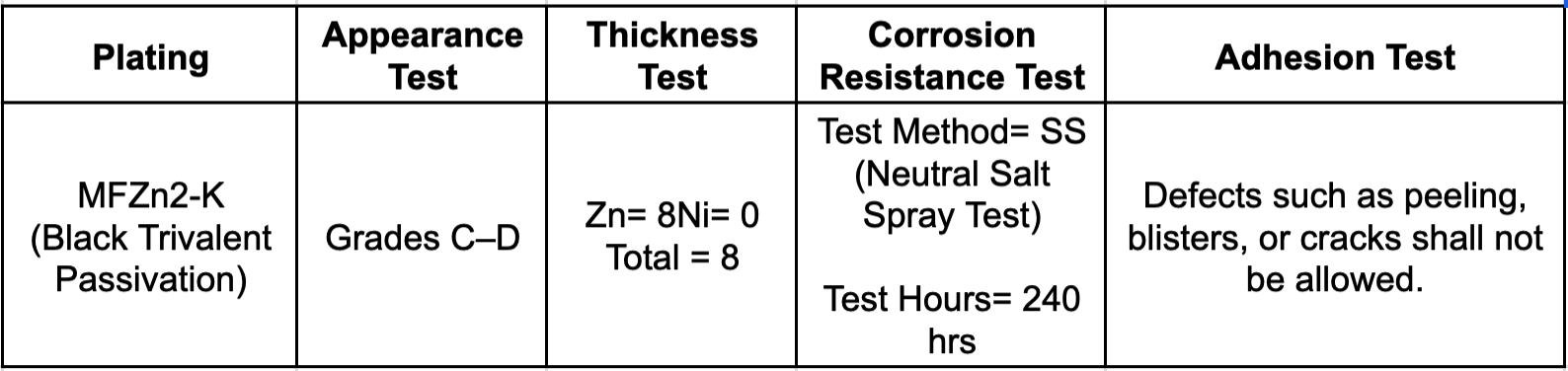

Below is a chart explaining the trivalent black passivate electroplating specification, MFZn2-K, for Honda, and its results from the various tests:

All of Great Lakes Metal Finishing’s electroplated coatings are inspected for the necessary items stated above. Inspection sampling methods, test items, and test positions are determined through ongoing discussions with GLMF and the client.

GLMF Offers Black Trivalent Plating Meeting Specifications MFZn2-K & MFZN 2TK for Automotive Parts

Great Lakes Metal Finishing offers trivalent black zinc electroplating as one of our many options for zinc plating. Our tight tolerance metal finishing work can accommodate a wide variety of black trivalent zinc electroplating specifications. We can achieve the desired plating thickness, bake cycle, or salt spray requirements for the most demanding automotive applications. We also provide trivalent yellow, hexavalent yellow, and trivalent clear metal coatings. Contact Great Lakes Metal Finishing today to learn more.